Impedance Level:

If we compare AT-cut and SC-cut resonators having the same

frequency and overtone, the motional inductance (L1) and motional

resistance (R) of the SC-cut resonator will be significantly higher than for the

AT-cut resonator, while the motional capacitance (C1) will be lower

in the same proportion. The static capacitance (C0), however,

will be nearly the same for the two. For oscillator applications, high

impedance is desirable if aging is important, because it reduces the effect of

the sustaining circuit on the oscillator frequency. The trade-off is that

high resonator impedance reduces the tuning range of the oscillator frequency,

limiting corrections for manufacturing tolerance and for aging. In VCXOs,

aging is, at most, a secondary consideration, so that the required tuning range

will determine the highest practical overtone. For either cut, the

impedance level increases roughly as the square of the overtone for a given

frequency, but also depends upon details of the resonator design.

Size:

For most applications, the sizes of the AT-cut and SC-cut

resonator packages are the same.

Cost:

Because of tighter orientation tolerances, the SC-cut is more

expensive to manufacture than the AT-cut, but for high-performance applications

this cost is more than offset by savings in oven complexity, and for many

applications the SC-cut is the only choice. For some applications where

thermal transient characteristics are less important, a modified (near) SC-cut

may be used. This provides essentially the same f - T curve as the true

SC-cut but allows looser orientation tolerances, thereby providing some cost

savings at the expense of thermal transient performance. Normally, cuts

having To much removed from 92°C will not provide the thermal

transient performance for which the true SC-cut is noted.

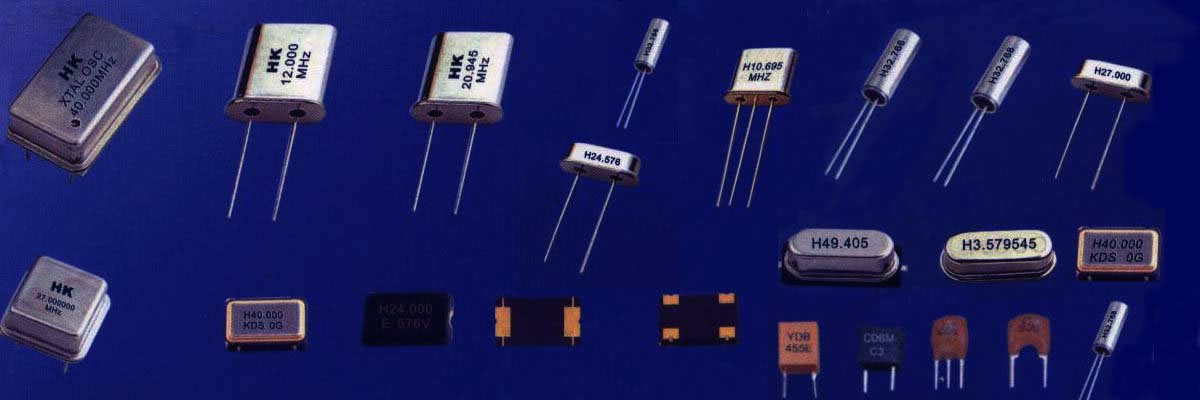

Quartz Turning Folk Resonators / Watch Crystal

The requirements of quartz resonators for wristwatch are:

small size, low power dissipation (including the oscillator), low cost, and high

stability (temperature, aging, shock, attitude). These requirements can be

met with 32.768 kHz quartz turning fork resonators. It is interesting to

know that 32768 = 215 or 1 Hz = 32768/215. In an

analog watch, a stepping motor receives one impulse per second which advances

the second pin by 6, i.e., 1/60th of a circle every second. The

32.768 kHz is a compromise among size, power requirement (i.e., batter life) and

stability.

Quartz wristwatches are sufficiently accurate, usually, while

worn as intended, i.e., on the wrist for ~16 h and off the wrist for ~8 h each

day. The accuracies degrade when the watch is off the wrist for extended

periods. The further the storage temperature is from the optimum temperature,

the faster the watch loses time. At temperature extremes, e.g., in a

freezer at - 55°C, or at the temperature of boiling water, wristwatches lose

about 20 s per day.

The angle of cut of the resonator used in wristwatches is such

that the zero temperature coefficient is at ~ 25°C, as shown in the following f

– T curve. This has been found to provide the highest probability of accuracy,

based on the typical durations and temperatures while the watch is on the wrist

and while it is off the wrist.

Type of Seal for Quartz Crystal Resonators

Solder Seal

Solder seal packages have several advantages. They have

lower lead-to-case capacitance than other types and therefore used in some

filter designs that require minimal junction capacitance. In addition, the

packages can be opened for rework that is sometimes helpful in meeting difficult

filter requirements. Their main disadvantage is that they cannot be sealed

without introducing contamination, and therefore they tend to have relatively

poor frequency stability.

Resistance Weld

These packages require more sophisticated sealing equipment

than solder seal, but the sealing process introduces less contamination,

resulting in better frequency stability. Resistance weld packages are

available in a wide range of styles, and all are economical choices for

long-term performance

Seam Weld

Seam weld sealing is the most widely used method today in

producing ceramic base/metal cover low profile SMD crystals and

oscillators. Performance and cost are similar to those resistance weld packages.